Everything you need to know about how HUCK works.

Huck bolts work differently than threaded bolts and nuts in that they are installed with industrial tools that provide a permanent solution. This makes them ideal for those looking for vibration resistance. Huck bolts are essentially two-piece recessed grooved pin and collar combinations where the collar sits on the pin and is pressed into the groove of the pin with a designated tool. The tool presses a collar of softer material into the pin, making the two-piece combination into an integrated, one-piece entity.

How to install thumb bolts?

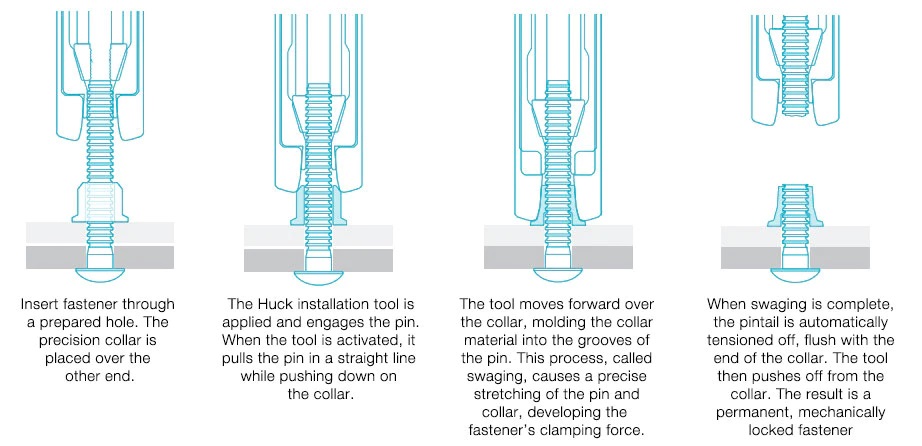

Huckbolt consist of two parts: the bolt and the collar. Install the huck bolts in advance. The pin diameter should match the hole size to achieve a tight fit and prevent lateral movement that would create a bolt.

Place the huck bolt collar on the other side of the pin head. The collar sits on the pin, and when the collar is swaged (compressed) into the pin's holder via a huck gun, the collar tool presses the softer material sleeve into the pin, forming the two parts into a strong, long-lasting combination.

During the initial stages of the installation process, the huck gun engages and pulls on the ring pin while pressing the assembly further onto the collar. The tool gradually presses the collar into the sleeve of the harder steel pin. Pin forging and press sleeves now combine to maximize metal-to-metal contact so unlike nuts and bolts, it won't come loose. The tensile strength of a Hucker bolt is determined by the number of grooves filled.

WHAT IS A HUCK RIVET?

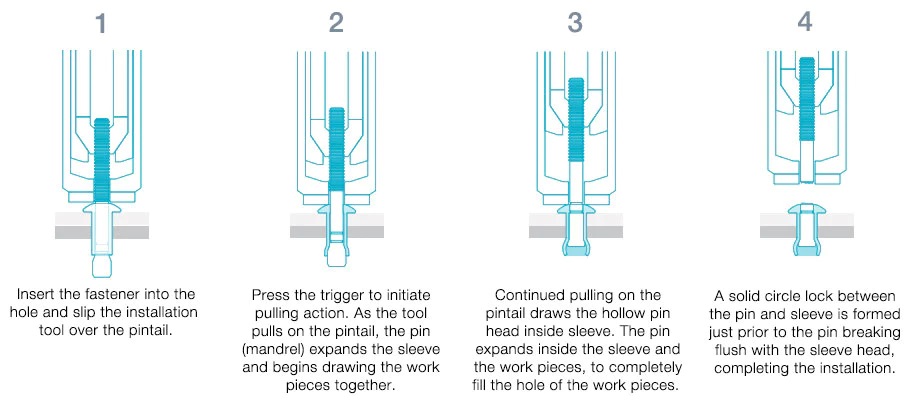

Huck rivets are a one-piece fastener that works differently to a two-piece HuckBolt. Huck Bolts requires access to both sides of the material, whilst a Huck rivet requires only one side access. This saves installation time. Huck structural rivets have an internal mechanism that locks a portion of the pin (mandrel) inside the rivet's body. This creates an additional layer of material that assists in increasing the rivets strength and makes them different to general purpose rivets.

HOW DO YOU INSTALL A HUCK RIVET?

Installation of a Huck rivet is similar to a standard rivet, however you will require a Huck gun or a structural rivet gun, as a standard rivet gun is not equipped with the correct jaws to install structural rivets on a continuous basis. To install a structural rivet, pre drilling of holes is required. Load rivet’s pin tail section into rivet gun. Insert rivets body into hole and activate gun. Upon activation the head of the rivet is pushed against the nose of the tool, whilst the tool pulls up the central pin. As a result, the body compresses, and expands on the blind side until it maxes out to approximately one and a half times the size of the original diameter. Resulting in a larger surface in which the two materials are effectively fastened together.

HOW HUCK BOLTS AND HUCK RIVETS WORKS SUMMARY.

Huck Bolt and Huck rivets are used in the fabrication of truck, truck trailers, ute trays, ute canopy bodies, emergency vehicles and numerous other steel fabrication applications where a vibration resistance fastener is critical to the application. At the conclusion of this blog, it is evident that Huck plays an important part of the fastener world and irrespective of the Huck fastener needed for your project, be assured that your project will end up as a successful one with the use of Huck.

Copyright © 2026 Wuxi Zhuocheng Mechanical Components Co.,Ltd. - All Rights Reserved.